This article reflects on my first 9 months of woodworking. Most resources for beginning woodworkers focus on techniques. However, technical details are only part of the full story. In this article, I'm covering another side of taking on the chisel. For me, the biggest theme over the last 9 months was about building my workshop and my skills within the reach of my financial means and free time. There is no youtube.com video on this topic.

It all started like that...

It all started with seven poorly finished maple steps in my split entry townhouse. We wanted to put the house on the market and the wood had over the years turned dull and dirty. I borrowed a palm sander from my mother-in-law and got to work. The smell of sawdust was my first hook. I then loved how it got clean, smooth, then how dramatic the grain shone through once I applied a few coats of finish. The house didn't go on the market and I still enjoy these stairs every single day.

One casualty of the house overhaul was the computer desk. The particle board monster was a bland piece of junk. But with a 1" particle board top, it now makes a solid base for my compound miter saw. Making

two computer desks became my very first project.

Motivation

I woodwork for fun and to get away from the computer. I go to my garage shop in bouts of 1 hour or so. I read about woodworking, shop for material, keep my patient spouse abreast of my plans, and blog sporadically. I design everything that I build, for the better and for the worst. I get surprised every time that I try to do something and it works exactly as expected. I'd like to make things on commission at some point, but I need to build a portfolio and my skillset.

Finding Information

In 2011, the challenge isn't to find information but to parse it. My reference is the

FineWoodworking.com website, which is worth the $35 annual fee a few times over. I find something on almost all topics, then search around with Youtube and Google. Public libraries have some print material as well, and I found that a few key items from Tautons such as "Basic Skills" series, "

Foolproof Wood Finishing" and "

Power tool techniques" makes fun reading on the bus (where there are no internet on my laptop).

Reading and listening cuts down on the

error part of learning by trial-and-error. I'd argue that spending most of my free time not in the shop reading or watching videos saves me a pile of money, time and made the hobby rewarding since day one. When confronted with the dilema of watching PBS's "

Rough Cuts" show or working in the shop, the shop won (sorry Tommy, maybe next year). Newcomers may enjoy the show, however.

Buying tools: Pandora, meet the box.

Tool buying is a bottomless pit. Most woodworkers joke about this, but the money needed to get going and keep on buying tools and material is very real. I've come up with some guidelines for myself which worked so far. The reader should keep in mind that a toolbox varies a lot from person to person: I'm interested in everything so the cost is higher.

- The reality check : In hindsight, it is not worth considering general woodworking if you can't put a few thousands of dollars into your shop in the first year, and if you can't afford to spend a hundred here and there from month to month. Otherwise, you'll torture yourself over what you don't have. If you can limit the number of tools and techniques to use, you can probably scale down these numbers.

- The incremental rule : I use what I have, and buy only what I need. I select the next project to use all/most of my tools, but includes a technique which requires something new. This gives the chance to develop my skills, appreciate what I've got, and amortize the cost over a long period of time.

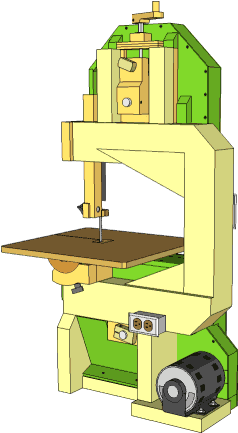

- The informed customer rule : I keep in mind that tools reviews may be written by professionals who are making a much heavier use of their tools than I ever will. Some entry level tools are going to work great for me (my RYOBI compound-mitre saw), but bigger ticket items benefit from a slightly larger investment (my bandsaw). Ah and oh yes, some reviewers dislike anything made in China, no matter whether it is good (for you) or not.

- The leap of faith : I initially enjoyed working with HomeDepot lumber because I didn't know any better. I eventually wanted to move to hardwood and rough lumber. It is cheaper, more flexible and versatile and way more beautiful. To mill lumber, I needed to apply what my wife coined as the "band-aid solution": buy all tools in on quick move. This set me back by $2k-$3K to get a 14+"bandsaw, a 6" jointer and a 13" planer. I threw in a drill press (you should too) while I was at it. Anything smaller than this is a bad investment, and larger may just be a waste of money for now. Make this jump only if you are really serious about it because you are about to burn a whole in your pocket, and bring home some 600 lb of steel and cast iron. I got all that I needed at BusyBee tools.

- The silent budget items : Hand tools are often as expensive as power tools. They are important, and great to work with. These can be bought as I go, and makes excellent birthday/Christmas presents. By default, I look first in the catalogs of high-end tools such as Lie-Nielsen and Lee Valley, then I check out other great places like Rockler.com and the local hardware stores. Unlike power tools, you buy hand tools to last you a lifetime.

- The lucidity rule : I keep tabs of expenses so I can start to budget properly later down the road. At first, budgeting isn't likely to make sense. I save all receipts and fill in these annoying warranty papers just in case that it matters later on.

- Cover all your bases : It helps to have a spouse who appreciates woodworking. Mine is great, and often talk me into buying what I think we can't afford. It helps that she is the main user of my projects. You can't change your spouse, but you can make your work be appreciated by selecting the right projects to work on.

Lessons learned

I'm glad to report that none of these lessons were learned by making catastrophic mistakes. This section isn't meant to cover how to do things: there are already a lot of very good resources for this. These lessons are more about less technical items that I realized from experience.

Each piece of wood is unique

Material is at the heart of woodworking. I played a bit with jewelery in the past and really liked how metalworking can be seen as "reversible": you can add, refill scratches, bend and unbend. Wood isn't like this. Wood is heterogeneous and anisotropic. You need to learn to read wood, find the best angle to cut, sand, joint or plane based on the grain and figuring patterns. Unlike metal, wood will not forgive a deep scratch. My first lesson in woodworking was that each piece of wood is unique and, although this sounds esoteric and fluffy, you better learn to care about it or else you are in for frustrations, tearouts and wood failures. I'll know that I'm good at woodworking when I'll start to look at wood grain for its aesthetic strength rather than its quirks.

Tolerating errors

How much error can one tolerate when joining two pieces of wood that are, say, two feet long: 1/8", 1/16", 1/64", 1/1000"? The eye is a sensitive sensor and tolerates no error, period. It is hard to believe, but the 1/1000" deep snipe left by my thickness planer is all that I can see when I mill a board. An important factoid about woodworking is that, with care, planning, tool maintenance and calibration, it is possible to be extremely precise. Whatever you do, do not tolerate errors until it is irreversibly glued. Dry fit everything, sand, sand, pare, scrape and sand some more. Once it is glued, however, move on because there is nothing that you can do about it anymore. One thing that I've learned is that the dent that bother you is likely not visible to the eye of anyone but yourself. And don't point out to others what is wrong with your work, people don't really want to know about that.

Be your most difficult customer but set some reasonable standards. There is no such thing as wasting time unless you are trying to make money.

Finishing: A scary beast

A subpar finish can negate all of your hard work in shaping a piece. Finishing is often seen as a fiddly and time consuming aside to woodworking. This doesn't need to be like this:

- Read enough about finishing to regard it to be something worth getting excellent at it. This is not an exercise in doublespeak: just like woodworking, finishing is highly technical, creative and the results are very rewarding.

- Test all finishing techniques on scraps. This will spare big surprises when you work on your real components.

- Finish before you assemble: it is easier, faster, more enjoyable. And if things go bad, you only need to scrap one component instead of the whole project.

Get the right tool for a job

The opposite not only will not be fun, but will probably give subpar results. My view is that if I don't have the tool, and can't afford to get it now, then I delay the project until I can. If you use the right tool, you will be amazed to see the work getting done before your eyes. I got some of these happy moments the first time that I sliced some veneer with the bandsaw, or cut a perfect mortise with a mortising chisel.

Design like an artist that thinks like an engineer

- Learn to use Sketch-up and build your design completely in 3D. Although I've modeled using Blender3D in the past, I needed to go through these awesome tutorials before I could do anything with Sketch-up. This means that I can now do woodworking even when there is no shop around! It is important to see the volumes and proportions clearly. Another important aspect is to plan how each piece will be joined with others. Of course, you can use pen and papers, but resizing and altering becomes a real burden. I've given up on paper already.

- Design with the assembly process in mind. Once the components are designed, the most important thing to figure out is the sequence in which they should be created, finished and assembled. The trickiest part to think about are the glue-ups: some parts have to be done simultaneously, and must be done fast. The last two conditions are somewhat contradictory.

- Keep things simple, but include one design element that you'll be proud to show once the piece is done.

Love your jigs

A jig is a piece that will not end in your final project. It can be as simple as a stop block and as complex as a sleigh for mitered splines in the corner of a box. Some jigs are versatile, and other are made for a single purpose. I really thought that making jigs was a major distraction from woodworking. However, a well designed jig will ensure precise and repeatable cuts and greatly enhance your results. When I began, I didn't have much scraps to use and had to buy lumber specifically for making jigs. This felt like a terrible waste of money. However, it doesn't take long before there is enough random scraps to go around. MDF is a composite material which is extremely cheap and works great for jigs. I usually make sure that I've got a few square feet of it in the shop just in case.

The tablesaw commends respect

Without the proper precautions, an accident can happen on the tablesaw without any warning signs. These are called kickbacks. Arm yourself with knowledge on

tablesaw safety. At first I was truly afraid of my tablesaw, so I read as much as I could. Eventually, I ended up feeling that I knew enough to use it safely. It sends shivers down my spine to think that I could have started working on it before researching carefully on the topic. I rarely read manuals unless things don't work properly. I can attest that, without a riving knife, I would have seen some solid pieces of lumber flying in my direction on two occasions. If you are not inclined to read manuals, you don't have to change but simply make an exception for power tools.

Know your tools before you plug them in, treat no cut as routine, cut no corners on safety.

Dust, noise, chips, hazards and fumes

This is not particularly insightful comments, but they are worth repeating.

- Dust : At first, I though that the dust and the shavings were cute. I liked their smell and didn't mind sweeping them. This changes overnight when I started using the thickness planer. I plan to get a central vac system, or dust management system in the lingo, over the next nine months... that's a $300-$500 dollars to budget.

- Chips : A good face protector is something that doesn't fog up. I have yet to find one but it is on my list. For now, I often get fed up and put my goggles down because the fog makes it more dangerous than wearing nothing.

- Noise : Protect your ears at all time. If you don't think that you need it, do it just to cut the noise from the world and work while in your own bubbles.

- Fumes : At first I didn't care. I thought that the smell of VOCs was part of the fun. However, after a few hours smelling this stuff, I bough a chemical respirator. I now consider speaking like Dark Vader to be more entertaining.

Outlook

It is interesting to see what kind of wisdom I thought to be worth noting in this post. I tried to stay away from technical lessons learned as many could be articles in their own right. I hope that my focus will shift from acquiring to creating with increasingly familiar tools and techniques.